Ngokuphuculwa kancinci kancinci kolwazi lokusingqongileyo, iipaliti zokhuni zirhoxa ngokuthe ngcembe ukusuka kwinqanaba lembali. Ngokudityaniswa nokunyuka kwamaxabiso okhuni, inzuzo yabo yokukhuphisana kwixabiso iyancipha ngokuthe ngcembe, kwaye iipalati zeplastiki sele ziqalisile ukubuyisela iipaliti zokhuni. Namhlanje, iipalethi zeplastiki zisetyenziswa kumashishini ahlukeneyo, kodwa wazi kangakanani malunga neepalethi zeplastiki?

1.Izinto eziphathekayo

Okwangoku, kukho iindidi ezimbini eziphambili zemathiriyeli eqhelekileyo kwimakethi yeplastic pallet: PP kunye nePE. Iipaliti zeplastiki ezenziwe kwezi zinto zimbini zinezinto eziluncedo kunye nezingalunganga, kwaye zinokuncedisana kwizicelo eziphathekayo. Ukubeka nje, iipaliti zeplastiki ezenziwe nge-PE ziyakwazi ukumelana nokubanda kwaye zisetyenziswa ngokubanzi kwishishini lokutya, kuba ukutya okuninzi kufuneka kugcinwe kwindawo ebandayo. Iipaliti zeplastiki ezenziwe ngezinto zePP zixhathisa kakhulu ukuwa, zinamandla okumelana neempembelelo, kwaye azinakwenzeka ukuba zonakaliswe ngenxa yokusebenza ngokungafanelekanga.

2. Iimathiriyeli ezintsha kraca kunye nemathiriyeli esetyenzisiweyo

Iipaliti zeplastiki zimveliso ezivuselelwayo. Iiphalethi zeplastiki ezisetyenzisiweyo ziya kuphinda zisetyenziswe kwaye zenziwe kwakhona zibe yimathiriyeli ekrwada, edla ngokubizwa ngokuba yimathiriyeli esetyenzisiweyo. Nangona iipaliti zeplastiki ezenziwe ngezinto ezintsha zihlala zihlala njalo, abathengi abahlukeneyo baya kuba neemfuno ezahlukeneyo. Kwiinkampani ezisetyenziselwa kuphela ixesha elifutshane kwaye zineemfuno eziphantsi zokuthwala umthwalo, iipaliti zeplastiki ezenziwe ngezinto ezintsha azibizi. Ngokuqhelekileyo, umbala we-pallet yeplastiki unokusetyenziselwa ukugqiba ukuba ingaba yinto entsha okanye into ehlaziyiweyo. Umbala wepallet yeplastiki yezinto ezintsha uqaqambile, ngelixa izinto ezihlaziyiweyo ziya kuba mnyama ngombala. Ewe, kuya kubakho imixube, efuna iindlela zobuchwephesha ezingaphezulu zokugweba.

3. Ukuthwala umthwalo kunye nokumila kwefonti

Umthamo wokuthwala umthwalo weepaliti zeplastiki ikakhulu kuxhomekeke kwizinto eziphathekayo kunye nobuninzi bezinto eziluhlaza, isitayela se-pallet kunye nokuba kukho imibhobho yensimbi eyakhelwe-ngaphakathi. Ngethuba nje inokuthi ihlangabezane neemfuno zenkampani ngokwayo, ubunzima be-pallet ngokwayo kufuneka ngokuqinisekileyo bube lula ngokusemandleni, okungekho lula kuphela kulawulo, kodwa nokugcina ukuthutha. iindleko. Ifonti yephalethi imiselwe ngokuyintloko ngokwendawo ezahlukeneyo zokusetyenziswa. Ingaba i-forklift yomatshini okanye i-forklift ye-manual, nokuba ifuna i-palletized, ingaba ifuna ukufakwa kwi-shelf, njl. zizinto zonke eziphambili ekukhetheni ifonti ye-pallet.

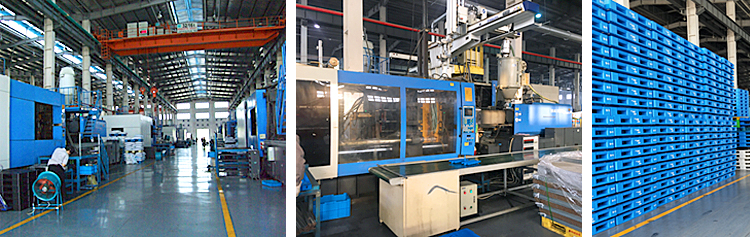

4.Inkqubo yokuvelisa

Okwangoku, iinkqubo eziphambili zeepaliti zeplastiki kukubumba inaliti kunye nokubumba. Isitofu sokubumba kukubumba inaliti ye-thermoplastic, eyenziwa ngokutofa izinto ezikrwada ezinyibilikisiweyo kumngxuma wokungunda osisigxina. Yeyona nkqubo yemveliso ixhaphakileyo. Iipalethi ezisicaba eziqhelekileyo kunye neepalethi zegridi zombini zibunjiwe. Iipalati zeplastiki zeendlela ezahlukeneyo kunye nemilo ziveliswa ngokweemfuno ezahlukeneyo zabathengi. Ukubumba ukuvuthela kukwabizwa ngokuba kukubumba umgongxo. Kudla ngokubakho imingxunya yokubumba kumphezulu wephalethi yokubumba, kwaye umbindi wepalethi awunantonga. Inkqubo yokubumba ivuthela inokuvelisa kuphela iipaliti ezinamacala amabini, kwaye ulwalathiso lwe-inlet luhlala luhamba ngeendlela ezimbini. Ngokubanzi, ixabiso leepaliti ezibunjiweyo zokuvuthela liphezulu kunelo leepaliti ezibunjiweyo zesitofu.

Iipaliti zeplastiki zithandwa ngamashishini kwiinkalo ezahlukeneyo ngenxa yokulula kwazo, ukukhuselwa kwendalo kunye nokusebenza kakuhle. Ngophuhliso oluqhubekayo lwe-Intanethi yeZinto, ukusetyenziswa kweepallets ezihlakaniphile ekugqibeleni kuya kuba yindlela yophuhliso. Ii-chips zifakwe kwi-pallets zeplastiki ukubavumela ukuba baqokelele ulwazi. Ukuhanjiswa, ukulandelela indawo, ukwahlula kunye nokuhlelwa kuhlanganiswe ukufezekisa ulawulo olubonakalayo lwekhonkco lokubonelela.

Ixesha lokuposa: Apr-26-2024